News

Updated 04/09/2025

Contact [email protected] for more information

April 2025

-

Upcoming Webinar Presentation by Dr. Yong-Yi Wang on Practical Girth Weld Evaluation Criteria (Tue, Apr 22, 12:00 PM – 1:00 PM EDT):

- PRCI-hosted webinar titled: MATH-5-3D: Practical Girth Weld Evaluation Criteria Considering Weld Strength Mismatch and HAZ Softening

- Registration link: Webinar – PRCI – MATH-5-3D

- Three test options for enhanced welding procedure qualification are proposed, including

- All-Weld-Metal Tensile (AWMT) Test

- Non-Instrumented Cross-Weld Tensile (CWT) Test

- Instrumented Cross-Weld Tensile (ICWT) Test

April 2025

-

CRES and Geosyntec are co-hosting the 4th Annual Pipeline Geohazards Forum to be held on April 16-17 in Houston, TX.

March 2025

-

Three staff members attended PRCI Research Exchange PRCI Research Exchange in early March 2025. Dr. Yong-Yi Wang made a presentation on Reinforcing Pipeline Segments Containing Circumferential Anomalies Subjected to High Longitudinal Stress/Strain. He highlighted the differences in hoop vs. longitudinal stress driven threats. He also pointed out deficiencies in some RP documents about repairing and reinforcing circumferential anomalies.

September 2024

-

Dr. Yong-Yi Wang will present the following tutorial and papers at IPC 2024, Calgary Sept 23-27:

- Tutorial on: Welding Practice and Linepipe Specifications for Enhanced Resilience of Girth Welds in Traditional and Emerging New Pipelines

- Four papers on:

-

-

- Key Elements and Best Practice in the Management of Circumferential SCC

- Essential Elements of a Holistic Framework for the Management of Geohazards

- Welding Procedure Qualifications of Girth Welds Suitable for Actual Field Conditions

- Toughness Evaluation and Integrity Assessment of Modern X80 Linepipe Welds for the Application of High Pressure Hydrogen Pipeline

-

February 2024

-

Dr. Yong-Yi Wang will present the following paper at the Asset Integrity Management of Critical Infrastructure Conference, AIM-2024, Orlando Feb 5-6

October 2023

- On October 26th, CRES, in collaboration with Pipeline Safety Institute, presented two exciting live webinars:

September 2023

-

PRCI recently published two webinars presented by CRES. The webinars focus on preventive measures against low strain failures of girth welds in newly constructed pipelines and risk assessment of existing pipelines.

Webinar 1: Mitigating Low Strain Girth Weld Failures – Recommendations on the Enhanced Linepipe Specifications and Girth Welding Practice | PRCI official announcement

Webinar 2 : Mitigating Low Strain Girth Weld Failures – Enhanced Design Requirements and Risk Assessment of Existing Pipelines | PRCI official announcement

May 2023

-

Dr. Yong-Yi Wang will present two papers at the API Pipeline Conference and Expo: Pipeline, Control Room and Cybernetics, Nashville, TN, May 1-3

- “Potential Safety and Integrity Challenges of Hydrogen Pipelines Subjected to Geohazards Loading”

- “Lessons Learnt from Girth Weld Failures of Newly Constructed Pipelines and Industry Responses”

https://events.api.org/2023-api-pipeline-conference-and-expo-pipeline-control-room-and-cybernetics/

-

PRCI is broadcasting a webinar where CRES will present research results for Recommendations on the enhanced linepipe specifications, girth welding practice, and design requirements (MATH-5-3B)

https://www.prci.org/NewsEvents/NewsArchive/260004.aspx

February 2023

-

Dr. Yong-Yi Wang presented “Girth Weld Failures at Low Nominal Strains – Overview of Issues: Scope and Current State of Research and Knowledge” at the Canada Energy Regulator Workshop on Girth Weld Area Strain-Induced Failures in Calgary, Alberta, Canada

https://www.cerdialogue.ca/girth-weld-workshop

-

Dr. Yong-Yi Wang presented “Considerations for Offshore Pipelines / Pipelines That Cross Navigable Waterways and Water Bodies” at DOE workshop – Roadmap for CO2 Transport Fundamental Research in Dublin, OH

https://web.cvent.com/event/2d60ec9a-c07c-4fe4-88f1-a37ca7db44c8/websitePage:5c30ffe5-b577-491f-8d8d-1f745b03e9ec

January 2023

-

Dr. Yong-Yi Wang presented “Recommendations to API 5L and 1104 for Improved Resilience of Girth Welds in New Pipeline Construction” at the API 1104/5L Joint Task Group in New Orleans, LA

November 2022

-

PRCI highlights major report authored by CRES, and makes it accessible to the public.

In its announcement about MATH-5-3B, PRCI states “recommendations that are critical to improving industry practice, including updates to standards, are provided in this report. The implementation of these recommendations is expected to greatly reduce the risk of similar failures in the future. They are helpful for responding to the safety advisories from CER and PHMSA.”

https://www.prci.org/Research/DesignMaterialsConstruction/DMCProjects/MATH-5-3B/101449/249051.aspx

October 2022

-

CRES Paper Won 2nd Place in the Best Paper Competition at IPC 2022

A CRES paper, IPC2022-87337 “Application of Strain Based Assessment In Support of Operational and Mitigation Decisions” won the second place at the 14th International Pipeline Conference held in Calgary, Alberta, Canada on September 26-30, 2022. This paper demonstrates that a properly executed strain-based assessment (SBA) can be applied effectively for making operational and mitigation decisions when a pipeline is affected by geohazards such as a landslide. The ultimate goal of a geohazards management program is ensuring pipeline integrity. SBA can be a key component to achieve the goal cost-effectively by making the right decisions at the right time.

-

Two other CRES Paper nominated for Best Paper Competition at IPC 2022

- IPC2022-87028 The Practical Benefits of Detailed Forensic Analysis

- IPC2022-87067 Measurement of Flaw Growth in Electric Resistance Welded Pipe Seams from Multiple Pressure Tests and Hold Time and Implications on Managing Pressure Reversals in Hydrostatic Tests

September 2022

-

Dr. Yong-Yi Wang is presenting a Tutorial at IPC 2022 titled “Enhanced Welding Practice and Linepipe Specifications to Improve Strain Resistance of Newly Constructed Pipelines“, co-authored with Steve Rapp and Russell Scoles from Enbridge. See the tutorial introduction.

July 2022

-

CRES recently completed three major reports under two PRCI projects (MATH-5-3B and MAT-1-4). The outcomes of these projects are expected to have lasting impact on the pipeline industry.

Report No. 1 – Identification of major contributors to girth weld failures of newly constructed pipelines (PRCI Project MATH-5-3B, Report No. PR-350-174507-R04)

This report covers detailed investigation of girth weld failures of newly constructed pipes aimed at identifying major contributors. These failures occurred during service or in hydrostatic tests. The major contributors were identified as (1) weld strength undermatching, (2) heat-affected zone (HAZ) softening, and (3) elevated stresses.

The outcomes of this work provided directions for the development of mitigative measures which are covered in Report No. 2.

Report No. 2 – Guidance on the effective use of high strength linepipes (PRCI Project MATH-5-3B, Report No. PR-350-174507-R06)

This report covers mitigative measures to prevent girth weld failures in newly constructed pipelines, including:

-

- Enhanced linepipe specifications,

- Improved girth welding practice,

- Test protocols that support the enhanced linepipe specifications and improved girth welding practice,

- Changes to design requirements that reflect actual field conditions,

- Managing existing assets that might be at the risk of having low-strain failures of girth welds, and

- Strategies for technology transfer through awareness and engagement of stakeholders.

Report No. 3 – Recommendations on process control for consistent toughness in girth welds produced by self-shielded flux-cored arc welding (FCAW-S) (PRCI Project MAT-1-4, Report No. PR-350-164500-R03)

FCAW-S process has some distinct advantage over its gas-shielded counterpart, e.g., easy to apply in challenging conditions. Historically, some girth welds produced by FCAW-S are known to have highly varying toughness. The concerns about the toughness variations have prevented a wider use of this process in certain parts of the worlds, e.g., North America. The work covered in this report focused on the understanding of factors affecting the toughness. This understanding has led to recommendations on process control to achieve consistent toughness. With proper process controls, it is shown that girth welds from FCAW-S processes can offer increased productivity and higher strength in comparison with welds made by manual SMAW processes with cellulosic electrodes which have been a dominant girth welding method for manual welds in North America. The FCAW-S process could be a viable process for mitigating weld strength undermatching which has been identified as a major contributor factor to girth weld failures of newly constructed pipelines.

June 2022

-

CRES presented Incorporating Strain Hardening and 3D Shape of Metal Loss into Corrosion Assessment (PRCI) at the EPRG-PRCI-APGA 23rd Joint Technical Meeting (JTM)

May 2022

-

CRES and Geosyntec have been awarded a contract by INGAA and the INGAA Foundation on a JIP titled “Recommended Practice for Geohazard Land Movement and Framework for Geohazard Management”

April 2022

-

CRES will publish 6 papers at International Pipeline Conference (IPC) 2022

-

- Understanding Principal Drivers to Burst Pressure and Local Deformation of Pipes With SCC Colonies

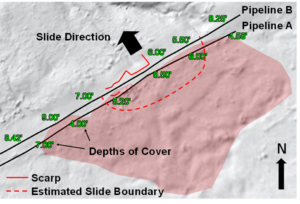

- Application of Strain Based Assessment in Support of Operational and Mitigation Decisions

- Measurement of Flaw Growth in Electric Resistance Welded Pipe Seams From Multiple Pressure Tests and Hold Time and Implications on Managing Pressure Reversals in Hydrostatic Tests

- Integrity Assessment of Pre-cracked Linepipe Used for Transportation of High Pressure Hydrogen based on ASME B31.12

- The Practical Benefits of Detailed Forensic Analysis

- Self-Shielded Flux-Cored Arc Welding – Practical Approaches for Improved Toughness Performance of Girth Welds in High-Strength Pipeline

March 2022

-

Case study – Fitness-for-Service Assessment for Effective Landslide Management. Read how CRES helped the operator quickly return its pipeline to normal operation pressure, saving the expense of costly field work.

Read More...

Fitness-for-Service Assessment for Effective Landslide Management

An integrated approach between hazard mitigation and fitness-for-service (FFS) assessment was used to address a pipeline impacted by a landslide in the eastern USA. Both the immediate and long-term integrity concerns were considered. A rapid FFS analysis determined that the line could be operated at normal pressure and that immediate site work was not necessary. A more refined analysis later determined that invasive field work was not necessary. Site work focusing on water management and installation of strain gages. The strain gages monitored the integrity of the pipeline, and a plan was developed if the gauge readings exceeded the limit. This approach allowed the company to continue operations safely and ensure the long-term integrity of the pipeline.

A geotechnical investigation suggested that a pipeline might have been impacted by previous and current landslides. The owner engaged CRES to conduct an FFS assessment and to work with a geotechnical specialist to develop necessary mitigation and monitoring measures. The FFS assessment estimated the strain demand imposed on the pipeline by the landslide, assessed the strain capacity of the pipeline, and determined the current integrity status and tolerance to further ground movement.

In February 2019, when the current ground movement was identified, information on the landslide and the pipeline properties was limited and still being collected. With the limited information, including the span and maximum movement of the landslide, CRES performed a preliminary assessment of the strain demand with simplified analytical models. Combined with strain capacity estimates from previous work for the same pipeline, CRES concluded that the strain demand was lower than the strain capacity of the welds in the affected segment. The pipeline was considered safe, by a comfortable margin. CRES worked closely with the operator and geotechnical experts to justify delaying any immediate field work and the line was allowed to operate at its normal pressure. If CRES had not determined the safety of the pipeline, field work would have increased the risk of destabilizing the saturated slopes during the early spring. Large side slope excavations would have been required to uncover the pipeline at a 10-foot depth of cover putting the workers and pipeline at greater risk.

After the initial discovery, the landslide characteristics and site-specific pipeline properties were collected by the Operator. Based on the updated information, CRES performed a refined assessment to obtain the strain demand and site-specific strain capacity. Pipe-soil interaction modelling indicated a lower strain demand than found in the preliminary analysis. After a comprehensive review of the pipe and welds, a case-specific strain capacity analysis focused on two manual tie-in girth welds. The analysis produced a higher strain capacity than the preliminary strain capacity estimates. CRES recommended against the stress relief of the affected segment due to the existing safety margin. In parallel, site stabilization work diverted ground water reducing risk. Strain gages were installed at selected locations, based on CRES analysis, to detect changes over time and ensure continued integrity. CRES provided intervention strain thresholds for mitigation actions.

The integrated approach for hazard management and FFS assessment ensured integrity and reduced the amount of field work, while the line continued to operate safely. The site work simultaneously addressed the immediate threat and provided a method to monitor the site for integrity into the future.

Yong-Yi Wang, [email protected]

-

CRES published 2 papers at Technology for Future and Ageing Pipelines (TFAP) 2022 Conference:

- Managing Standards with Evolving Industry Practice – Lessons Learned from Girth Weld Failures in Newly Constructed Pipelines

- Strain-Based Design and Assessment of New and Ageing Pipelines

-

CRES Presented Vintage Girth Weld Properties and Flaw Characteristics for Tensile Strain Capacity Assessments at PRCI Research EXchange (REX) 202

February 2022

-

CRES presented Burst Pressure Prediction of Pipes with SCC Using Intelligent Flaw Interaction Rules at PPIM 2022

September 2021

-

CRES published the first rapid strain-based assessment tool GwiseTM to help operators grade pipelines impacted by geohazards.

June 2021

-

CRES led the development of interim recommendations published by PRCI

-

Dr. Yong-Yi Wang is one of the main editors of the ASME book Pipeline Integrity Management Under Geohazard Conditions (PIMG) published in 2020

-

CRES presented Integrity-Focused Geohazards Management for Pipelines at ASME IPG conference

-

CRES presented Strain-Based Design and Assessment of New and Ageing Pipelines at TFAP 2021 conference

May 2021

-

CRES presented two webinars on Interim Recommendations for the Mitigation of Low-Strain Girth Weld (Part I, Part II)

-

CRES 2017 JIP report on the management of ground movement hazards is available through INGAA

April 2021

-

CRES presented two webinars on the burst pressure prediction of pipes with SCC colonies

-

- Webinar I, 04/08/21 – Improved Burst Pressure Prediction of SCC Colonies – Development of Intelligent Flaw Interaction Rules

- Webinar II, 04/22/21 – Improved Burst Pressure Prediction of SCC Colonies – Evaluation of Intelligent Flaw Interaction Rules Using Full-Scale Burst Tests

February 2021

-

CRES made presentations in 9 subject areas at PRCI virtual research exchange 2021

December 2020

-

CRES conducted full-scale burst tests with its newly commissioned test facilities with a maximum pressure capacity of 6000 psi.

October 2020

-

CRES and Enbridge made a presentation at an INGAA meeting titled “Methods to Mitigate Undermatched Girth Welds” on October 29, 2020.

September 2020

-

CRES published 11 papers at the 2020 International Pipeline Conference (IPC) among a total of 226 papers published for the entire conference. Five of the 11 papers were selected for “live” presentations during a two day virtual conference on September 29-30. CRES had the most “live” presentations among all conferences participants.

August 2020

-

CRES worked with Geosyntec and Golder to develop a guidance document on the management of landslide hazards for pipelines.

May 2020

-

CRES presents PRCI Webinar on Tensile Strain Capacity (TSC) of Pipes Containing Corrosion Metal Loss.

April 2020

-

CRES published 11 papers at IPC 2020

-

- Structured Response Plan after a Ground Movement Event

- Improved Linepipe Specifications and Welding Practice for Resilient Pipelines

- Management of Ground Movement Hazards – an Overview of a JIP

- Development of Lifting and Lowering-in Plan for the Control of Construction Stresses

- A Review of Pipe-soil Interaction Models for Strain Demand Estimation

- Material Properties and Flaw Characteristics of Vintage Girth Welds

- Burst Pressure Prediction of Pipes With SCC Colonies – Development of Intelligent Flaw Interaction Rules

- Burst Pressure Prediction of Pipes With SCC Colonies – Evaluation of Intelligent Flaw Interaction Rules Using Full-Scale Burst Tests

- Estimation of Tensile Strain Capacity of Vintage Girth Welds

- Effects of Biaxial Loading on the Tensile Strain Capacity of Girth Welds with Weld Strength Undermatching and HAZ Softening

- Rational Limits of High-low Misalignment in Girth Welds

February 2020

-

CRES presents PRCI Webinar on Assessment of the Tensile Strain Capacity (TSC) of Vintage Girth Welds (Part I, Part II).

October 2019

-

CRES is one of the sponsors for IPC 2020. IPC 2020 is now open to accept abstracts.

September 2019

-

CRES presents PRCI Webinar on Pipeline Lifting and Lowering-in Stress Application Tool.

Click to view the webinar recording

Learning outcomes/benefits of attending:

- Understand the importance of managing stresses during lifting and lowering-in.

- Learn how to use the Pipeline Lifting and Lowering in Stress Application Tool (CNST-2-2) to develop lifting plans that can be used to ensure that stresses during lifting and lowering-in do not exceed a given value.

- Learn how trade-offs can be managed between different construction conditions, such as number of sidebooms, spacing between sidebooms, or lifting height.

- Learn how the Pipeline Lifting and Lowering in Stress Application Tool (CNST-2-2) deliverables fit in the broader context of a construction project.

Who should attend?

Pipeline construction personnel and pipeline design engineers.

July 2019

-

CRES presents PRCI Webinar on Guidance for Assessing Buried Pipelines after a Ground Movement Event.

Presenter: Yong-Yi Wang, Center for Reliable Energy Systems

Project Team Leader: Michael Cook, ExxonMobil

Program Manager: Thomas Marlow, PRCIThe research conducted by Dr. Wang set out to improve pipeline design to better accommodate significant localized ground movement such as that caused by landslides, earthquakes, or subsidence/settlement. When such a ground movement event occurs along the right-of-way (ROW) of a buried pipeline, it is imperative that the pipeline operator determine whether the ground movement is a threat to pipeline integrity in order to protect those responding to the event, those living near the affected ROW, and the environment.

This webinar will discuss the research findings and provide guidance to pipeline operators responding to a ground movement event.

Expected Benefits/Learning Outcomes from attending this webinar:

- Understanding factors that must be considered in response to a confirmed ground movement event,

- Being able to make critical decisions immediately after an event, such as continued service at full pressure, pressure reduction, or shutdown, and

- Ability to make use of the structured response plans with systematic considerations of an operator’s objectives, tolerance to risks, site-specific soil and pipeline conditions, and availability of information with known time constraints.

Who Should Attend?

- Pipeline design engineers

- Pipeline integrity engineers, managers, specialists

- Operations personnel

May 2019

-

Dr Yong-Yi Wang were invited by the Board of the Australian Pipelines and Gas Association (APGA) and the members of the Association’s Research and Standards Committee (APGA-RSC) to the 22nd Biennial Joint Technical Meeting (JTM) held in Brisbane, Australia, from 28 April to 3 May 2019.

The technical program for the JTM consist of some 36 papers that represent the very latest and best research being done through the cooperative programs of PRCI, EPRG and APGA. Dr Yong-Yi Wang presented three papers during the meeting:

-

- Low Strain Capacity Girth Welds of Newly Constructed Pipelines and Its Implications in Integrity Management

- Strain Capacity of Vintage Girth Welds and Integrity Management Process

- Application of Essential Welding Variable Methodology in Addressing Low Girth Weld Strain Capacity Issues and Path to Standard Revision

March 2019

-

CRES is a lead organizer and contributor to the ASME Conference Asset Integrity Management – Pipeline Integrity Management under Geohazard Conditions.

Dr. Yong-Yi Wang gave a keynote lunch presentation on Integrated Hazards Management and Fitness-for-Service Assessment for Integrity Management of Pipelines Subjected to Geohazards. Dr. Wang also moderated a panel session on Gaps and Roadmap (related to geohazards management). CRES published three papers:

- Strain-Based Design and Assessment – Concepts and Gaps

- Tensile Strain Models and Their Applications

- Low Strain Capacity Girth Welds of Newly Constructed Pipelines and Mitigative Approaches

January 2019

-

Dr. Yong-Yi Wang made a presentation on Girth Welding in the Age of Evolving Steel Manufacturing Processes and under Realistic Field Conditions to the API 1104/5L Joint Task Group at the 2019 Exploration & Production Winter Standards Meeting.

September 2018

-

Dr. Yong-Yi Wang is the honoree of the ASME Distinguished Lecture Series at IPC 2018.

Read More... The Pipeline Systems Division of ASME states “The 2018 edition of the International Pipeline Conference established the Distinguished Lecture Series in honor of Dr. Yong-Yi Wang to recognize his significant technical contribution to the pipeline industry. Dr. Wang has been a significant technical contributor to the International Pipeline Conference as a Track Leader, and author. While serving as a steward of the IPC Strain Based Design track, he also contributed technical content to various tracks with a total of 146 papers to his credit both at IPC and at other conferences. Dr. Wang has also been a contributor to many industry organizations such as API, ASME, CSA, PHMSA, PRCI, and others. Through all of his industry activities he has demonstrated his personal commitment to the industry and the engineering profession. The goal of the Distinguished Lecture Series is to present technical content that was produced over the past several decades that have provided a foundation for modern pipeline technology. Dr. Yong-Yi Wang and his industry collaborators are the embodiment of the 2018 International Pipeline Conference theme of Building the Future Now.”

-

CRES published 5 papers at IPC 2018.

-

- Assessment of Dents under High Longitudinal Strain

- Attributes of Modern Linepipes and Their Implications on Girth Weld Strain Capacity

- Tensile and Compressive Strain Capacity in the Presence of Corrosion Anomalies

- Burst Pressure of Pipelines with Corrosion Anomalies under High Longitudinal Strains

- Burst Pressure of Wrinkles under High Longitudinal Strain

March 2018

-

Dr. Yong-Yi Wang is recognized as the Outstanding Researcher by PRCI.

The Executive Assembly & Executive Board of PRCI presented the Distinguished Researcher Award to Dr. Yong-Yi Wang “for dedicated and distinguished service and scientific achievements that have enhanced the integrity, reliability and environmental performance of energy pipelines around the world.”