Girth Welding and ECA

-

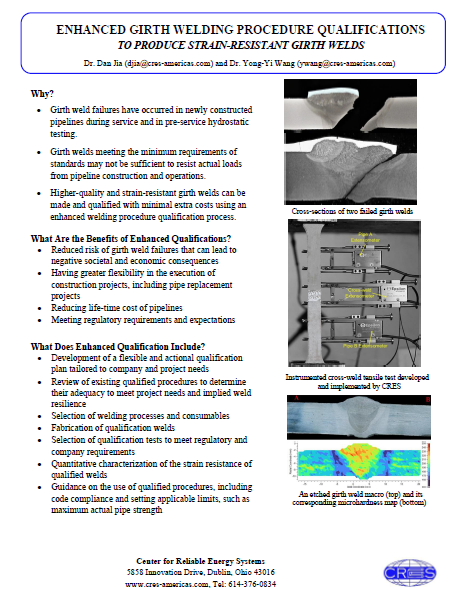

Enhanced girth welding procedure qualifications to produce strain-resistant girth welds

-

Guidance document for the proper use of API Standard 1104

- Provide background and rationale for various clauses in API 1104

- Provide example problems

-

Guidance document for the proper use of API Standard 1104

- Provide background and rationale for various clauses in API 1104

- Provide example problems

-

Supplemental requirements for welding procedure qualifications and field practice to produce strain-resistant girth welds

- Selection of welding procedures, consumables, and welding parameters

- Additional procedure qualification tests and requirements

- Repair procedures and limits

- Inspection procedures and flaw acceptance criteria

- Achievable strain tolerance level

-

Welding procedures to improve the strain capacity of girth welds

- Design and implementation of special welding procedures to compensate for the detrimental effects of weld strength undermatching, high-low misalignment, and weld flaws

-

Proper treatment of low fracture toughness

- Understanding the significance of low toughness related to pop-in

- Provide recommended procedures to deal with low toughness

-

Construction quality management for welds with high-low misalignment

- Guidelines and limits on high-low misalignment under different conditions

- Interaction of high-low misalignment with other features, such as welds with undermatching strength

-

Welding and integrity assessment of high-strength pipelines (≥X70)

- Essential variables for welding high strength pipelines

- Test protocols to obtain accurate mechanical properties

- Assessment methodology for traditional and advanced designs

-

Welding procedure design and weld property prediction of X80 and lower grades

- Optimization of welding procedures through the prediction of weld and HAZ properties

-

ECA and flaw acceptance criteria for the construction of large-diameter pipelines

- Flaw acceptance criteria per API 1104, CSA Z662, or other equivalent codes

-

ECA and flaw acceptance criteria for low temperature construction

- Flaw acceptance criteria using advanced analysis, i.e., crack-driving force vs. low-constraint toughness

-

ECA to account for high-low misalignment

- Flaw acceptance criteria explicitly accounting for the high degree of misalignment

-

ECA of offshore risers and flowlines

- Flaw acceptance criteria that explicitly account for fatigue and/or harsh environment

-

ECA of liquid lines with fatigue concerns

- Review the application of API 1104 Appendix A Level 3 procedure

- Make recommendation on implementation

-

Development and standardization of state-of-art fitness-for-service assessment procedures

- Support standard revisions in test protocols and assessment procedures

Case Study – Essential Welding Variable Method (EWVM)

Representative Publications